Linatex has used Computational Fluid Dynamics (CFD) modeling and specialist design principles to develop the new range of Linatex Genesis HydrocyclonesTM. Incorporating a number of new features, this cyclone will provide improved classification efficiency and product recovery.

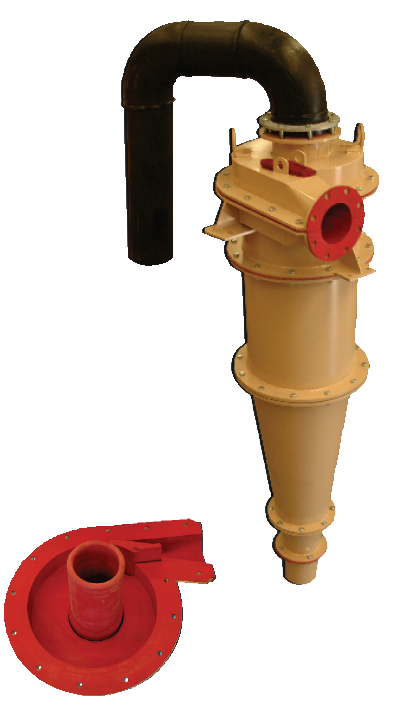

- An interchangeable inlet wedge is a unique feature of the Linatex Genesis HydrocycloneTM. The wedge allows operators the opportunity to quickly change the size of the inlet and fine tune the cyclone performance without physically removing it from the process line.

- The feed slurry is introduced to the body of the cyclone in a tall rectangular ribbon. The feed transition physically moves the solid particles closer to the wall of the cyclone, minimising the distances travelled during the separation process and results in improved efficiency. CFD modeling was used to design the round to rectangular feed transition area to reduce operational pressures and minimise wear and operational costs.

- The scrolled and swept inlet head allows the cyclone feed to be introduced to the cyclone without interfering with the separation stream. This ensures all forces acting on the slurry during separation are maximised and turbulence is minimised.